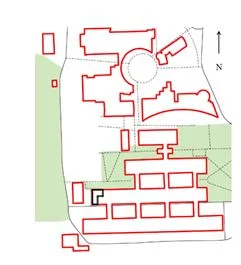

Surrounding area and geometry

Figure 1: Location of the NBERT building in relation to CIT campus

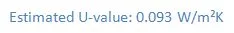

The National Built Energy Retrofit Test-bed (NBERT) is a 223m2 educational building that is part of the wider Cork Institute of Technology (CIT) main campus in Bishopstown, Co. Cork, Ireland. The NBERT building is a renovated part of the existing CIT main campus building which was designed in 1974. The retrofit project was completed in 2012 and now functions as live test-bed for research activities for micro-grid, ventilation and thermal comfort applications. Since NBERT has an on-site weather station located on top of the building at a height of 5 m above roof level, the data portal contains actual data about the climate. Please feel free to have a look at it!

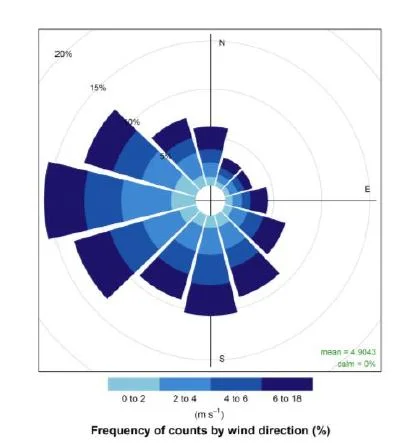

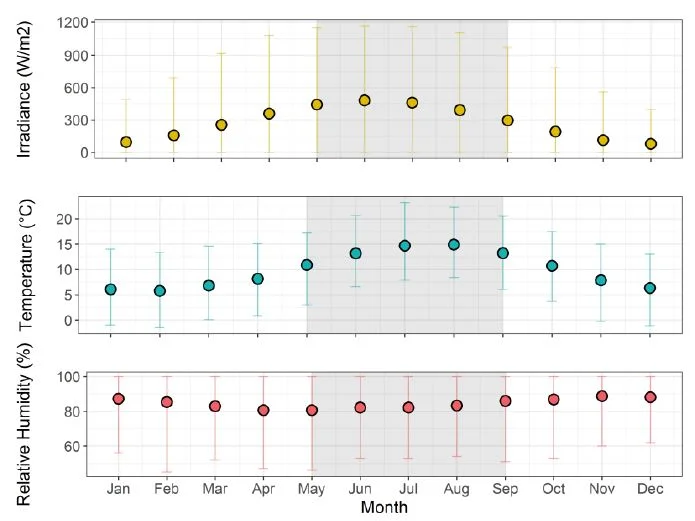

Local climate and surrounding area

Cork has a warm temperate oceanic climate which is characterised by large amounts of precipitation and relitively mild conditions year round with warm summers. Typically, shoulder seasons (Spring and Autumn) in Cork have mean temperatures of between 8.6°C and 10.6°C, maximum temperatures of between 17.2°C and 20.5°C and minimum temperatures between -0.2°C to 0.1°C.

Figure 2: Wind rose for Cork Aiport

Figure 3: Mean, maximun and minimum external conditions in cork airport using TMY3 from meteonorm 7 (cooling season shown shaded)

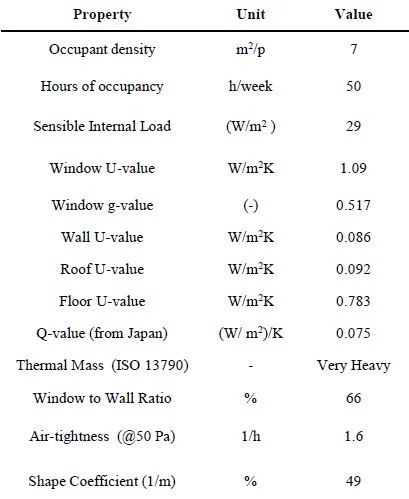

Building properties

The main orientation of the building is west facing where the surrounding buildings are of the same height. The building has mostly unobstructed views to the northwest and southwest but does have a building obstructing the west façade. Information on the buildings thermal properties are indicated in the thermophysical properties section below. The ECG19 benchmarks (Energy, 2000) are also referenced for comparative purposes. The building is open from 08:00am to 10:00pm daily during each academic semester.

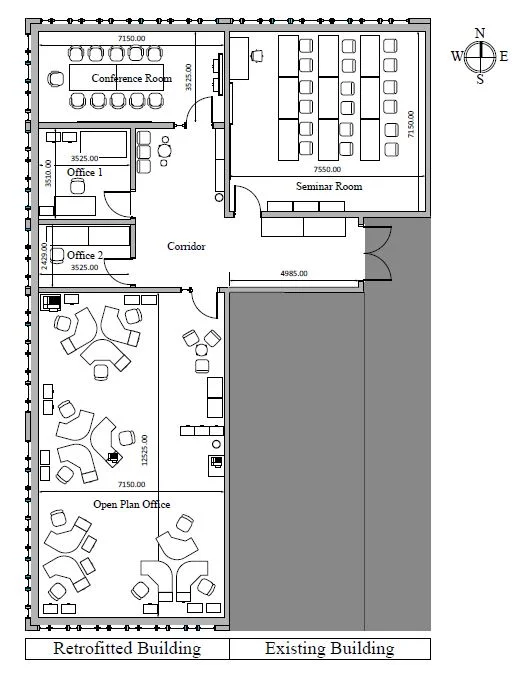

Due to the nature of retrofit in live buildings, solutions will have to be phased and as non-invasive as possible. A phased, modular, scalable, felxible, durable external retrofit with an intermediate internal retrofit is the most suitable design solution (coupled with a largely off-site build). The refurbished building, shown in figure 4, which delivered a considerable reduction in energy conumption due to an energy efficient deep-retrofit solution has functions as both a lecture room and office space is also the National Build Energy Retrofit Test-bed (NBERT) where data is gathered continually on internal and external conditions.

Table 1: Building properties

Figure 4: Retrofitted building

The button below allows you to download the pdf documents about the building. Please contact us if you want to have the dwg documents.

Thermophysical properties

In order to make the building more isolated, the thermophysical properties of the buidling have been changed. Now, we can observe a greater thermophysical performance compared to the old building created in 1974.

To download the materials data sheet, clik on the material

The materials with an asterisk are found on the CIBSE website

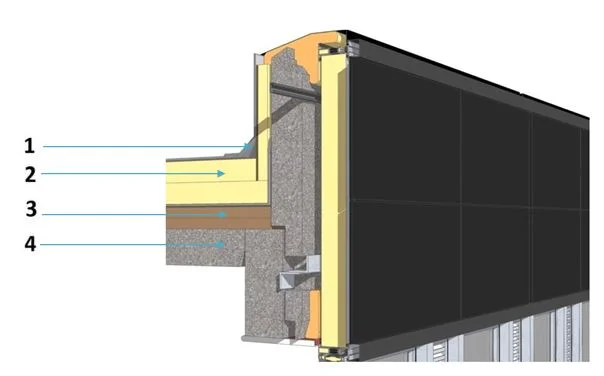

Glazing system

The existing glazing is made up of single glazed, clear float 6mm glass with a U Value of 6.0 W/m2K. The glazing unit, integrated into the new AMSTS125 fenestration system, consists of a Saint-Gobain sealed, argon filled, low-e coated, triple glazed external component, interstitial venetian blinds and a fourth pane of clear float inner glass completing the glazing transparent component. Details of the system are outlined below. The blinds are adjustable by running a control mechanism through the window system and fitted to the mullion on the inside.

1. and 2. Saint-Gobain Low-e coated Planitherm Total + 90% Argon filled gap

3. Saint-Gobain *Planilux clear float

4. 16mm interstitial slat blind

5. 4mm Clear Float

Figure 5: Glazing module layers

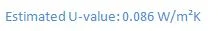

Walls

The existing wall structure in CIT comprised of a 100mm internal block, an un-insulated air gap and an external concrete aggregate panel approximately 125mm thick (items 1 & 3 with an air gap substituted for item 2 in the table below). Vertical support mullions, designed and supplied by AMS, were installed externally to the aggregate panels. These support the glazing system and the Kingspan Benchmark system which comprises a 125mm insulated panel, carrier rails and a 12mm ceramic granite panel as shown in figure 6.

Figure 6: External wall build up

Thickness (m) λ (W/mK) R-value(W/m²K)

1. Existing internal block* 0.100 0.79 0.13

2. BASF Walltite Spray foam 0.086 0.02 4.11

3. Existing aggregate panel* 0.125 0.22 0.57

4. Air gap* 0.030 0.19

5. Kingspan Benchmark ceramic granite panel 0.012 1.40 0.01

6. Kingspan support rail (air gap) 0.037 0.21 0.18

7. Kingspan KS1100 insulated panel 0.125 0.02 6.25

8. AMS Support Mullion 0.125 7.69 0.13

Roof

The existing roof comprised of 150mm concrete slab, 25mm polystyrene insulation and a poured asphalt covering (items 1 -3

below. Include a new asphalt covering on the new roof build up). The insulation was upgraded to 200mm thick Kingspan

Kooltherm rigid insulation.

Thickness (m) λ (W/mK) R-value(W/m²K)

1. Cast Concrete Slab* 0.150 2.00 0.075

2. Cork Board* 0.025 0.04 0.625

3. Asphalt* 0. 005 0.50 0.001

4. Kingspan Kooltherm rigid insulation 0.200 0.02 10.00

Figure 7: External roof build-up